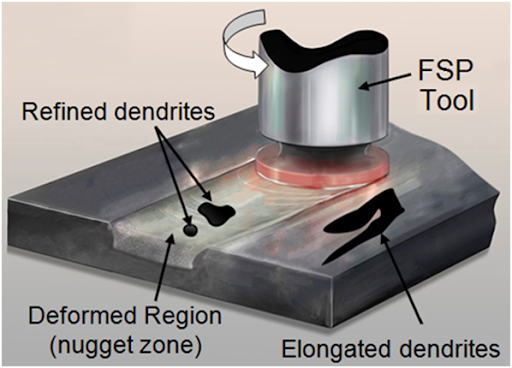

Friction stir processing is a solid-state method to develop composite especially surface composite. In this method, a non-consumable rotating tool is used to make a composite. The tool is allowed to be inserted inside the workpieces up to a certain depth to process the material. The tool will be rotating with a certain rotating velocity and also travel at a certain travel speed. With the rotation of the tool, the material will also stir and rotate which produces dynamics recrystallization in the material and forms fine grain materials.

Fig. Frictions

stir processing

The development of fine grain material plays important

in the changes of mechanical and material properties. It

improves the hardness, strength, toughness, and wear resistance of the

material. These are the important mechanical properties to

make any mechanical component.

To make composites with the help of FSP, grooves or

holes need to be made on the upper layer of material to be

processed. This can be done by any milling machine. Hard ceramic

particles such as SiC, B4C, MoS2, Al2O3, Tio2 can be filled in this

grooves. The first step is to close this groove with the pinless tool.

Then a non-consuming rotating tool is employed over the work surface

with the predecided rotational speed. The FSP tool consists of a pin and

column. The pin part will penetrate inside the workpiece and force the

material to stir along with it. Because of this, the material will go

into intense plastic deformation and dynamics recrystallization

happens with the processed material.

Fig.

FSP tool

No comments:

Post a Comment